Analysis methods for fiber distributions

We develop new methods to analyze how fiber properties vary, in order to provide better decision support in pulp production and the design of different parts of the process.

The Need for More Than Averages

In modern pulp and paper manufacturing, maintaining consistent product quality and making efficient use of resources both require more detailed information than traditional average-based measurements can provide. Our project introduces innovative methods to analyze fiber property distributions rather than averages, offering a new dimension of insight into pulping processes.

From Averages to Patterns – A New Perspective on Fiber Data

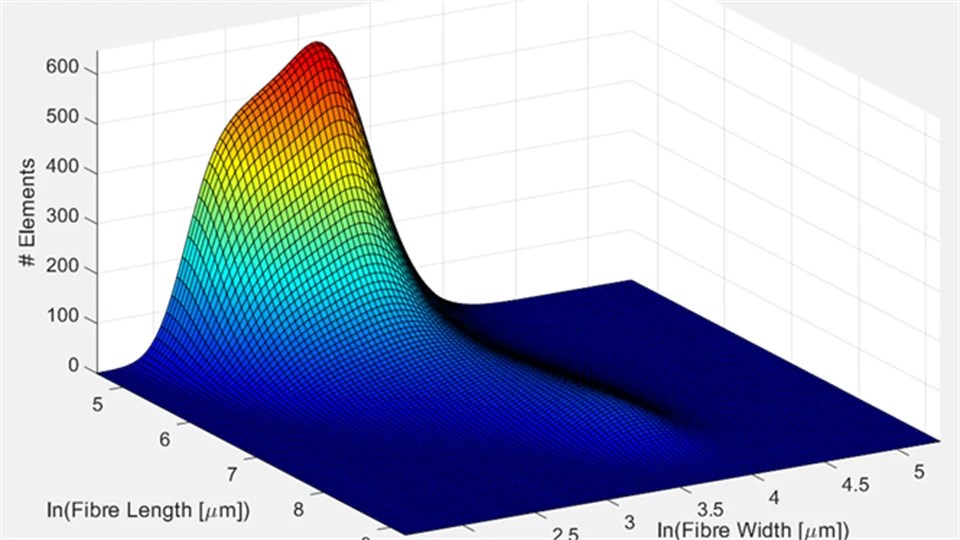

The project builds on the discovery that the full distribution of fiber properties, such as length, width, curl and fibrillation, carries more predictive power for paper strength and other product properties than mean values alone. By focusing on the shape and behavior of these distributions across pulping processes, we develop decision support for both real-time process control and design of unit processes.

At the heart of the approach is the concept of Impact Maps, visualizations of how fiber distributions change under processing. These maps reveal patterns that traditional measurements miss, providing detailed information on how heterogeneity develops.

The methodology also addresses a long-standing challenge: the statistical treatment of multidimensional fiber data. By determining how factors like sample size and instrumental differences affect measurement accuracy, we ensure that our findings are robust and comparable across devices and conditions.

Industrial Benefits and Future Potential

Our research not only advances basic understanding of fiber mechanics but also provides immediate industrial benefits:

· More sensitive tools for assessing refining effects.

· Decision support for process adjustments and unit design.

· Improved control over pulp uniformity and quality.

In the longer term, these innovations enable mills to reduce resource use, increase product performance, and adapt to new material demands with greater flexibility.