Cold start

The project aims to develop a stable working methodology in the long term in order to be able to use the EBM process to repair details.

But also utilize the process's properties, high energy and vacuum environment, to create new material combinations that are not possible in other manufacturing methods.

Background

The EBM process has previously been rejected as a useful process for repairing already manufactured parts or resuming an interrupted print. The main problem with a “cold start” is that the process is carried out under vacuum and at high temperature, but also that the surrounding powder needs to be semi-sintered before melting can take place to avoid charging the powder bed and causing downtime.

The Sports Tech Research Centre has long worked with the EBM process and its properties. With some modifications to the process, both repair of components and start-up of an interrupted build have been completed. However, only a few samples have been produced, but the results have proved positive.

Objectives

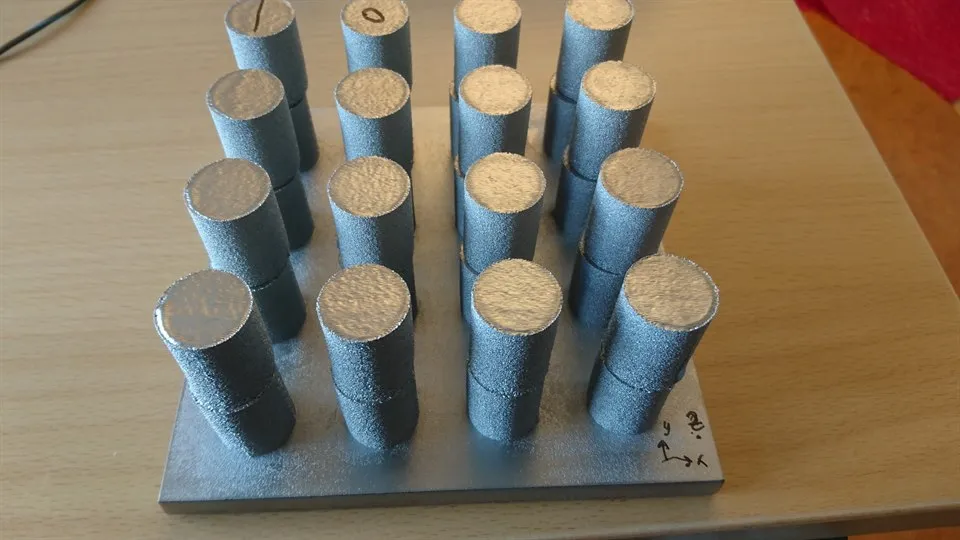

To develop samples and demonstrate that the EBM process can be used for repairs of already manufactured parts. The pilot project is expected to result in a number of test rods in stainless steel 316L, Ti64 material and a combination of both. All test rods will be characterized, among other things the microstructure will be studied.

Project period

May 2018-2020

Researcher

Lars-Erik Rännar, project manager

Carlos Botero and Per Skoglund, technically responsible

Funders

The project is funded by the Rolf and Gunilla Enström Foundation for Research and Development.