Sio Grafen

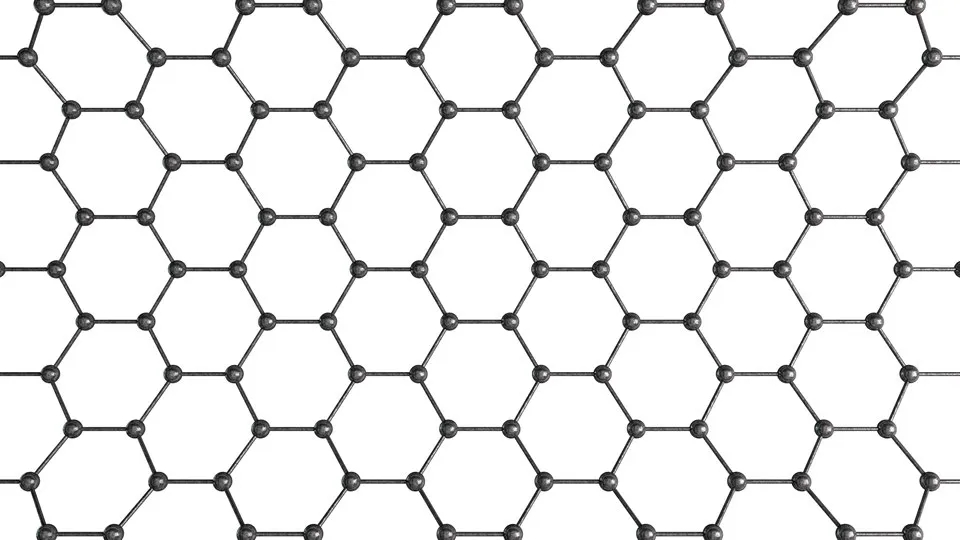

Additive Manufacturing (AM), also known as 3D printing, is a rapidly growing manufacturing method. To make more advanced products, new materials are needed. In this project, we will develop an electrically conductive material using graphene.

In addition to Mid Sweden University, project partners are 2D fab, which is a graphene producer, Lasernova who specialises in laser processing and Wematter who develops and manufactures AM machines.

Functionalise graphene

Industrial manufacturing using AM is growing rapidly and by developing an electrically conductive material for AM, companies will gain an advantage in product development and production. We will therefore develop in the project a composite material for the “Powder Bed Fusion” AM technology, which is the dominant in the industrial market. In Powder Bed Fusion, a powder material is melted together using laser to build up the object you want to manufacture.

Graphene is an excellent material choice for the composite material as it has high electrical conductivity and can be manufactured in an environmentally friendly way.

In the project, we will look at how to functionalise graphene to get a better material mix and how the fluidability of the powder can be improved to work in Wematters AM machines.

We will also work on how to selectively make GO conductive with laser processing during manufacturing and find out which electrical conductance can be achieved while maintaining material strength.

Materials with electromagnetic compatibility

There is a great market potential for leading AM in the industry where there is a special interest in manufacturing leading parts that meet different electromagnetic compatibility (EMC) requirements. The introduction of electric vehicles gives rise to new EMC requirements that need to be addressed and AM with leading materials is a very interesting manufacturing method.

Facts

Project period

220401—240630

Partners

Research centers

Subjects

Research groups

Project leader

Project members