Aluminum‑based batteries open the door to future energy storage

Aluminum-based batteries are a promising candidate for next-generation batteries. Their potential to store a lot of energy, be relatively cheap and have lower environmental impact make them an attractive option, but how to optimize their performance and overcome the challenges?

Researchers at Mittuniversitetet are leading a three-year research project that received just over SEK 5 million in funding from the Energy Agency to focus on studying aluminum-graphitic dual ion batteries.

– The project is an important step towards the market for long-term durable batteries. We investigate aluminum alloys anode and electrolyte to create deeper understanding and develop new approaches. The goal is to develop aluminum-graphitic dual-ion batteries that perform even better. By contributing to a more sustainable energy storage technology, we benefit the whole society, says Ghadir Razaz, project manager and researcher at the FSCN Research Centre.

Aluminum-based batteries are interesting from a sustainability perspective because aluminum is a very abundant element in the earth. Aluminum-based batteries also have the potential to store a lot of energy, and the raw material is also cheaper and more readily available than some other materials. Research into aluminum-base batteries has so far mostly been devoted to cathode materials, while anode materials have received less attention, which the researchers want to change.

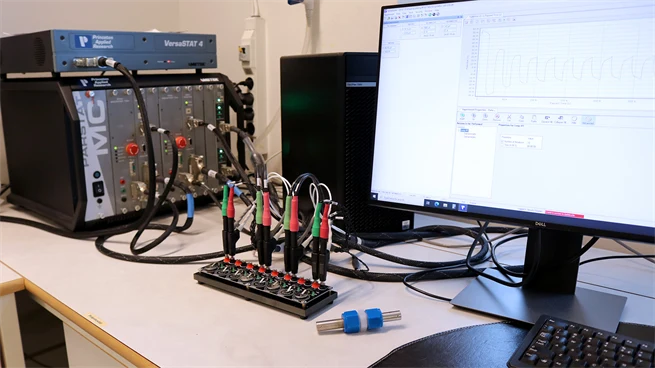

Laboratory experiments will, among other things, be carried out at Mittuniversitetet, but also at the Ångström laboratory at Uppsala University. Photo: Christine Grafström, Mid Sweden University.

– We know that there are some challenges such as the aluminum anode can have problems with oxide layer and corrosion, which affects the performance of the battery. We have recently shown that controlled corrosion of an aluminum alloy anode can improve battery performance. Now we want to move forward to develop aluminum graphitic dual-ion batteries and we are putting particular focus on the aluminum alloy anode and electrolyte, says Ghadir Razaz.

Within the framework of the project, laboratory experiments will, among other things, be carried out at Mittuniversitetet, but also at the Ångström laboratory at Uppsala University. In the project, the researchers from Mittuniversitetet and Uppsala University are also collaborating with Montanuniversität in Austria.

Learn more about the researchproject

Contact:

Ghadir Razaz, project manager and researcher at the FSCN Research Centre, ghadir.razaz@miun.se, +4610-142 80 92

Contact