The lab that tests anything from tents to quilted jackets

At the Sports Tech Research Centre's Materials Testing Lab companies can come and test their products. Gneis, who specialise in outdoor wear for children, come several times a year. In the lab they can test everything from wear and tear to water resistance.

The harsh fabric rotates, rubbing against the cloth stretched tightly in the machine. This gives a measure of how durable the material is. If the material proves to be not particularly durable, it might not be the most appropriate choice for functional garments for children.

Martinadale abrasion test.

“This lab is great for assessing such things. Once or twice we’ve decided not to use a particular textile after having tested it here,” says Sara Björkebaum, designer and product developer at Gneis.

She and her colleague Anna-Carin Forsberg have driven from Åre, where the company’s product development and purchasing departments are located. They think it’s great to have such a lab only 100 km from their business.

“Normally samples are sent off to a lab and the lab then sends back the results. Being able to watch while the tests are run makes it easier for us to detect things that we wouldn’t have been able to see from a report,” Sara Björkebaum goes on.

“And you understand what goes on a lot better,” Anna-Carin Forsberg adds.

A laboratory in great demand

The Sports Tech Research Centre’s textile testing laboratory opened in 2011 and was called the Textile Lab. It was funded by an EU project, the intention of which was to bring the university and industry closer together. Today the lab has been renamed the Materials Testing Lab because other materials, such as plastic and metal, can also be tested.

Anna-Carin and research engineer Kajsa checking tear properties of the fabric.

“We have an ongoing project called the Sports Tech Innovation Initiative, where the aim is to strengthen companies’ competitiveness and their ability to renew themselves,” says Kajsa Nilsson, research engineer and responsible for the lab’s activities.

She says that the companies come from both the outdoor and the industry sectors.

Plastic crates with company names on are lined up on a shelf in the lab. Lundhags, Eivy, Hillebergs and Woolpower are a few of the logos on the crates. Local companies that can come to Mid Sweden University to find out if their products fulfil their intended purpose.

“Many of them have very high demands concerning what their products must perform in respect of both environmental targets and quality,” Kajsa says.

Here they can test everything from durability to water resistance – and their demands are generally very high. When the lab at the Sports Tech Research Centre was built, companies were asked what they needed to accelerate their product development. An open test lab was one of the responses.

“That’s why we’re not accredited as many other labs are. We want our lab to be open,” Kajsa goes on.

Testing what textiles can perform

Sara and Anna-Carin from Gneis have planned to spend the entire day at the lab. The company has high demands regarding quality and environmental targets and they have a list of chemicals that they do not want in their textiles.

One of the things they want to do today is to see how the textile they have brought along functions in the cold, a test that involves the use of liquid nitrogen. Using the gas, the air can be quickly cooled to -20 degrees and a special machine can then show how tear resistant the material is under those conditions.

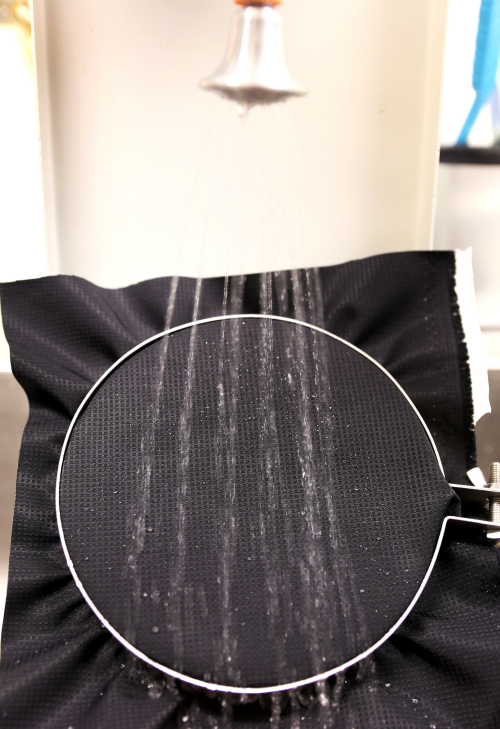

Checking water repellency with spraytest.

While they are waiting to run the cold test, they test the fabric’s resistance to abrasion and water. By means of a spray test they can see how good the material’s water resistance is.

“We test to see if water runs off or if the material gets very wet – it’s the actual finish of the textile that we test. We can also test water columns, where the membrane in the material is tested to see if any water can penetrate,” Kajsa explains.

By allowing a large piece of cloth to be thoroughly sprayed with water they can see how the material reacts. This particular cloth does not get wet at all; all the water has run off. A chart on the wall shows a scale that the test technicians can follow, ranging from dry to soaking wet.

“I’ll fill this one in,” says Sara pointing to the first image on the scale, where the cloth is driest.

Top marks in other words.

The values displayed on the computer from the tensile tester, where two gripping arms slowly but surely tear the cloth apart, also indicate good results.

“This cloth appears to be extremely durable,” observes Anna-Carin.