Consolidation of fibre‑based materials

We are developing new ways to enhance pulp-, paper- and wood-based materials. By improving their mechanical properties – such as strength, stiffness, and moisture resistance – our goal is to make it easier to replace fossil-based products with sustainable, bio-based alternatives.

A changing industry

Global paper production amounts to around 420 million tonnes per year. Of this, 240 million tonnes come from recycled fibres, while 180 million tonnes are virgin pulp – produced through chemical, semi-chemical, or mechanical processes. The Nordic countries play a key role in this sector, thanks to vast forest resources and a net annual forest growth of approximately 50 million cubic metres. Around 150 million cubic metres are used for sawn wood products, and another 25 million tonnes go to pulp and paper production from sawmill chips and pulpwood.

Over the past 10–15 years, the demand for printing and writing paper has declined significantly, while demand for packaging and hygiene products has increased. At the same time, there is growing interest in plastic-free, water-resistant packaging – which places high demands on the material’s performance.

The challenge of water

Lignocellulosic fibres, which make up wood-based materials, naturally attract water. As a result, conventional paper products often dissolve or weaken in humid conditions unless they are treated with environmentally harmful chemicals. Developing water-resistant, strong materials without such additives is therefore both a major challenge – and a great opportunity.

A new method to activate the lignin

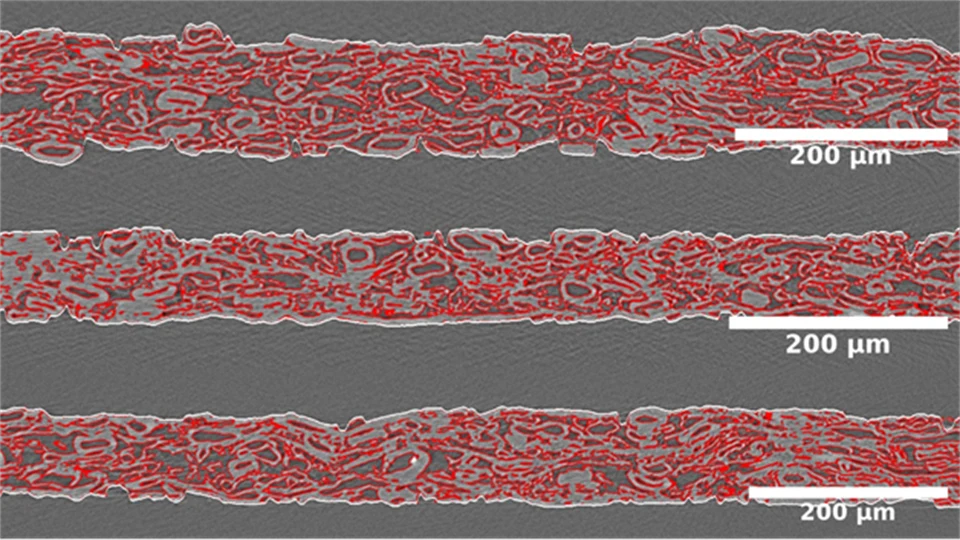

Researchers at Mid Sweden University have developed a technique that activates the lignin – the natural "glue" in wood – during pressing, drying or calendering. This enables the lignin to participate in creating strong bonds between fibres, without the need for chemical additives. The method can also be applied in moulded pulp systems.

One concrete example is hot-pressing of CTMP-based paper (chemi-thermomechanical pulp), where sheets are treated for varying durations – for instance, 1 second versus 30 seconds – to enhance material strength. In conventional papermaking, hemicellulose at the fibre surfaces typically acts as the bonding agent, as it is soft enough to intermix with hemicellulose from neighbouring fibres. With this method, the lignin also contributes, further strengthening the material.

What we aim to understand – and improve

To further improve material performance in an industrial context, our research focuses on three key areas:

- Gaining a deeper understanding of how softened lignin and hemicellulose interact at the fibre surfaces.

- Exploring the bonding kinetics that influence dry and wet strength.

- Investigating new material softening strategies to further enhance specific strength as a function of time and temperature.

Contact