New industrial production solutions with super‑duplex materials

In the AMSUSS research project, researchers want to find out how well high-performance stainless super-duplex steel works together with electron beam melting. The hope is that the new technology will enable industries to manufacture their products in a more cost-effective way in the future.

"No one has tested this in electron beam melting before, but we already have promising results on the process development of the material," says Lars-Erik Rännar, project manager for AMSUSS.

At the Sports Tech Research Centre, researchers and doctoral students are working to find answers to whether it is possible to use a special type of high-strength stainless steel, a so-called super-duplex alloy, in additive manufacturing using electron beam melting. The research is part of the AMSUSS (Additive Manufacturing of Super-duplex Stainless Steels) project, which started in mid-2021, in which several industry partners are involved.

"We have extensive experience of electron beam melting at the Sports Tech Research Centre, and we already have a strategic collaboration with Sandvik Additive Manufacturing. GE Additive/Arcam EBM and Alfa Laval are also participating in this project," says Carlos Botero, researcher in the project.

The industrial players are involved in different phases of the research project, where Sandvik Additive Manufacturing contributes with its material expertise and with the raw material in the form of powder. GE Additive/Arcam EBM is the equipment supplier and Alfa Laval is the end customer.

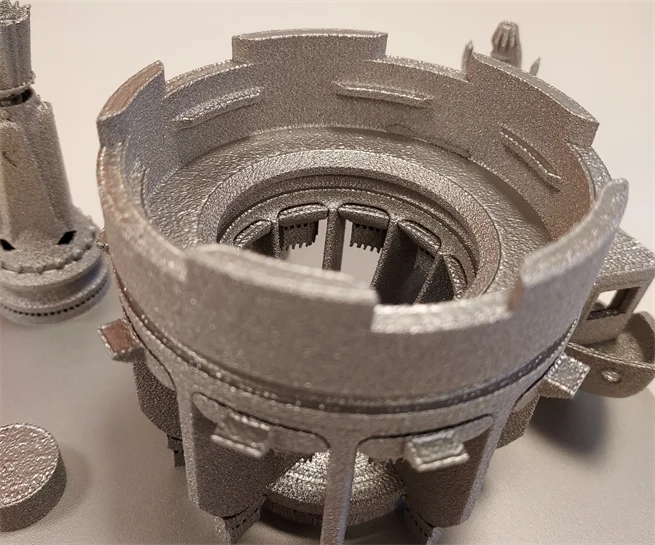

"We have been able to carry out experiments with real geometries, that is, a kind of complex drawing of what a possible end product could look like, in the new material. In this case, a variant of a part for a separator that can be used in industry to separate different types of liquids," says Stefan Roos, doctoral student in the project.

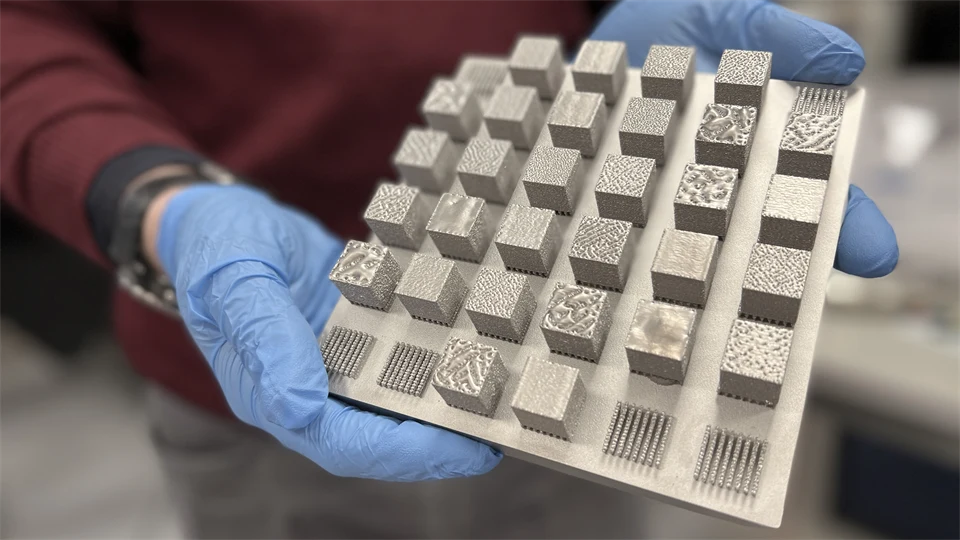

Stefan Roos has conducted scientific experiments and manufactured hundreds of sample geometries to optimize process parameters for both material quality and process efficiency. Here he shows some of the test geometries to Lars-Erik Rännar.

Electron beam melting, which is a technique where an electron beam melts metal powder and builds up a shape layer by layer, the researchers hope will contribute new opportunities to revolutionize the industry in the future.

"Alfa Laval wants to look at different types of technologies that work best with super-duplex alloys. Electron beam melting, which is one of them, contributes to less material waste and can also reduce lead times in production. At the same time, we must ensure that the material meets the requirements set where the quality and standard are maintained," says Lars-Erik Rännar.

Close-up of a part of a separator that PhD student Stefan Roos made using electron beam melting and process parameters developed in the AMSUSS project.

"From our perspective, the AMSUSS project is an important study to evaluate electron beam melting (EBM) as an additive manufacturing technology for advanced stainless steels, such as our super duplex material Osprey® 2507," says Mikael Schuisky, at Sandvik Additive Manufacturing.

"One of our goals is to compare the EBM process with the other AM technologies we use to produce super duplex components today, and evaluate the advantages and limitations we discover along the way," he concludes.

The project runs until May 2024 and is funded by the Knowledge Foundation. Read more about AMSUSS on the project page.