av

Stefan Roos dissertation

At the end of October, Stefan Roos defended his doctoral thesis in which he investigated the possibilities of combining the material stainless steel with electron beam melting – one of the new technologies in the field of additive manufacturing. His dissertation has led to several interesting results.

"How you melt and create your stainless steel products plays a major role in determining the properties the material eventually acquires, and with this technology we can control it very carefully," says Stefan Roos, who recently completed his doctorate at Mid Sweden University.

Additive manufacturing, what is commonly referred to as 3D printing, is on the rise. The Sports Tech Research Centre at Mid Sweden University, where Stefan Roos has completed his PhD, is at the forefront and is among the leaders in Sweden and the world, mainly in the method of electron beam melting of metal. The new technology is seen as a complement to both casting and milling of industrially produced metal products.

"The conclusion of my thesis is that it works very well to use an electron beam to melt this material," he continues.

Stefan has worked with different process settings that define, for example, how hot it is in the chamber where the steel is melted, how much energy there is in the electron beam, and how fast it travels and how it moves when it melts.

"Today, the technology more or less completely lacks process parameters for stainless steel beyond the lab level, thus limiting the possibility of applications, despite the fact that the materials are used in everything from cutlery and pots to advanced industrial applications in, for example, chemical, power, marine and pulp industry.

In short, the process in the machines involves heating a piece of tungsten – an element that can withstand extremely high temperatures – so that it becomes so hot that it starts to emit electrons. The electrons are then accelerated to almost half the speed of light and thus possess a lot of energy in the form of motion. They are then "pushed" into the material, which consists of metal in powder form. When the electrons meet the material, the kinetic energy is transferred and the material is heated and melted. This happens very locally as the surface that the beam hits is typically about 250 micrometers in diameter.

"This is a layer-on-layer process where you melt one thin layer at a time. Each layer that is added is between 50 and 100 micrometers thick. Then the process is repeated with different melts in each layer until you have built the component you are looking for.

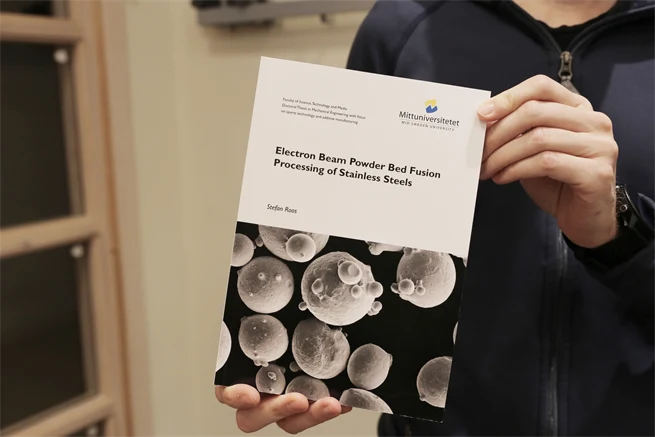

Stefan Roos' doctoral dissertation, in which a close-up of the metal powder used in the process adorns the front page.

Stefan's doctoral dissertation entitled "Electron beam powder bed processing of stainless steels" can be divided into two parts.

"The first part of the doctoral thesis is linked to the TROJAM research project, which investigates how well one of the most common stainless steels, 316LN, works together with electron beam melting.

"The second part is part of the AMSUSS research project, where a more high-performance super-duplex stainless steel, 2507, is tested in combination with electron beam melting. The project is a collaboration between several larger companies and is basically aimed at one of the companies in the project that wants to be able to convert one of their components to be manufactured using this method instead. It can contribute to a clear improvement if they do not have to test new molds or implement several changes in the production process. Instead, it is easy to adapt the geometry," he says.

The results of the doctoral thesis will hopefully be able to contribute to new ways of using additive manufacturing.

"The field has developed incredibly much just since I started, when there were hardly any scientific articles published on the subject. Now it's starting to be very specific things that are being researched. I am very much looking forward to continuing to teach and research further in similar projects in the future and try to develop or adapt the process to different materials or adapt materials to the process," concludes Stefan.

The research projects to which Stefan Roos' thesis is linked have been funded by the European Regional Development Fund and the Knowledge Foundation.

The page was updated 8/12/2025