Industry Ready for Immersive Remote Operation – New Needs Analysis Highlights Clear Requirements and Opportunities

A new needs analysis shows that forestry, mining, and manufacturing companies are ready to advance remote operations with immersive technologies. High demands on image quality, ergonomics, and usability remain, with AR seen as a key enabler.

A new needs analysis shows that companies in the forestry, mining, and manufacturing sectors are ready to take the next step in remote operation using immersive technologies. At the same time, expectations regarding image quality, ergonomics, and usability are high, and several stakeholders identify augmented reality (AR) as a key enabler for remote operation and guidance.

Clear Industry-Driven Requirements

The needs analysis was conducted within the framework of the research project IMMERSE and is based on interviews with companies in the forestry, mining, and manufacturing industries in both Sweden and Finland. The results indicate strong interest in immersive remote operation, provided that the technology is stable, intuitive, and easy for operators to use.

- Industry is clearly ready, but the requirements are also well defined. AR support, low latency, and high usability are essential for the technology to become a practical tool in operators’ day-to-day work, says Professor Mårten Sjöström, projectleader for IMMERSE at Mid Sweden University.

Several companies point out that VR headsets are not suitable for prolonged work tasks. Instead, screen-based immersive solutions combined with AR support are considered a better match for operational needs.

AR Highlighted as Critical for Safety and Decision-Making

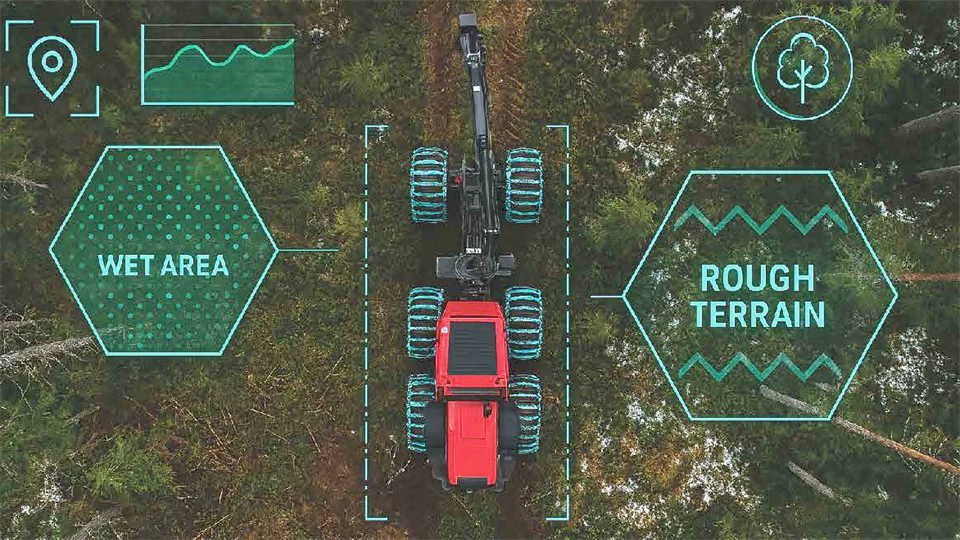

The analysis identifies AR overlays as a key function for improving both safety and efficiency. Such overlays can present digital information on top of live camera feeds, including terrain warnings, work zone boundaries, object recognition, and machine status, but also sequences of working instructions, providing operators with continuous remote guidance. For many stakeholders, AR is not seen as an optional add-on but as a necessary decision-support tool for effective remote operation and guidance in practice.

- It is clear that industry wants technology that strengthens operators’ situational awareness. AR overlays can provide better control, higher safety, and at the same time reduce cognitive load, says Professor Janne Heikkilä, project leader at the University of Oulu.

Significant Potential for Rural and Remote Regions

The needs analysis also highlights the importance of immersive remote operation for sparsely populated regions, where long distances and skills shortages make it difficult to staff heavy industrial roles. By enabling operators to control machinery from remote locations, immersive technologies, together with AR-based remote guidande, can support recruitment, regional development, inclusion, and more sustainable industrial production.

Operator Experience – A Key Success Factor

Companies emphasize that “the technology only works if operators want to use it.” Ergonomics, clear visual feedback, and an appropriate level of immersion are critical. If interfaces are perceived as cluttered, overly intense, or too slow, operators are likely to reject the system.

As a result, operator experience and ergonomics emerge as decisive success factors for large-scale implementation- an insight that the IMMERSE project is now taking forward in its continued development work.

- Industry perspectives are essential for developing technologies that deliver real value. Our next step is to integrate remote operation and AR solutions based directly on feedback from the companies involved, concludes Mårten Sjöström.

What is Immersive Remote Operation and AR?

Immersive remote operation refers to a setup where an operator controls a machine from a different location, supported by imaging systems and sensors that create the experience of being physically present on site. This technology can reduce occupational risks, improve working conditions, and increase access to specialized expertise.

AR – Augmented Reality involves overlaying digital information onto a live camera view, functioning as a remote guidance layer for the operator. This may include visual indicators such as obstacle markers, work zone boundaries, load movement, or machine status, but also instructional symbols like arrows. For the operator, AR functions as a decision-support tool that enables safer and more efficient operation. Similar technology is already used, for example, in automotive reversing cameras.

VR – Virtual Reality presents a fully digital environment. VR headsets are widely used in the gaming industry, but also in industrial contexts such as product development - from design to prototyping, as well as for training and education.

About IMMERSE

The IMMERSE-project aims to transform remote operations through augmented and immersive technologies, addressing the specific challenges and skills shortages of the Aurora region. Its objective is to improve access to and use of specialized expertise in remote areas, with a strong focus on sustainability and inclusion. The project is funded by the EU’s Interreg Aurora programme.

Learn more about IMMERSE:

www.miun.se/immerse

Contact