EBM components for ITER fusion reactor

Components needed to build the fusion technology test reactor (ITER) can be successfully manufactured using 3D printing EBM method. Progress in this direction was reported by Andrey Koptyug as representative of the research group at the last meeting of the International Project ITER II.

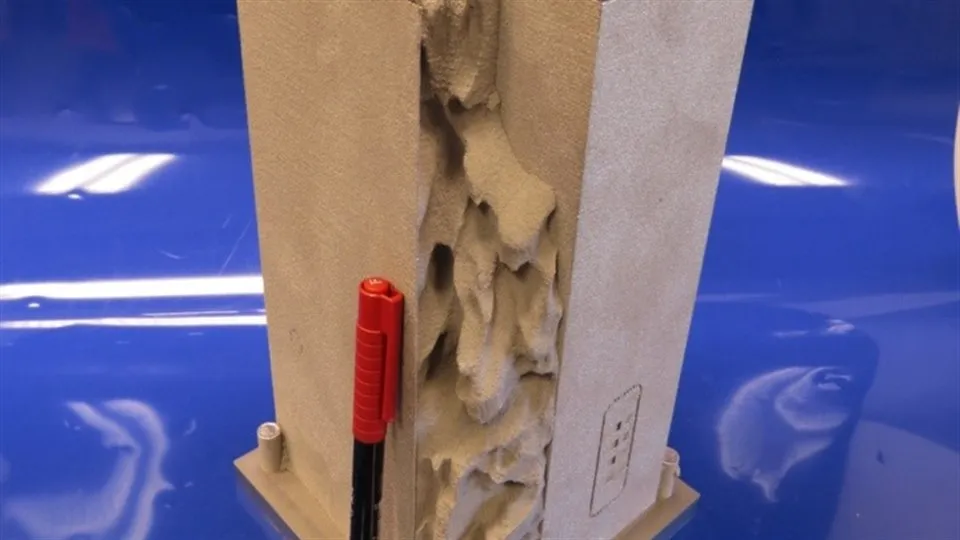

The Sports Tech Research Centre's role in the project has been as leading expertise in EBM and additive manufacturing. The project was the second step in a feasibility study on additive manufacturing (3D printing) of grade 316 stainless steel, one of the key material for making reactor walls. This steel, especially when made by EBM, can withstand extreme conditions demanded for the walls of the test reactor constructed in southern France.

316L stainless steel is a material that can withstand large temperature differences without affecting its mechanical properties. Therefore, it is perfect for the production of the forcedly cooled reactor elements located behind the tungsten tiles that line the walls of the inner chamber and is exposed to hot plasma.

Manufacturing these elements with traditional methods is costly and takes a long time because thousands of blocks needed for the reactor are all different. So additive manufacturing known to provide 'freedom of shapes' has been suggested as a possible solution. The assignment for the Swedish group including Mid Sweden University, Stockholm University, Chalmers University of Technology and Swerea KIMAB was to prove that it can actually be done, and that the properties of materials and components meet the high demands.

The project ran for four years during which the technology for producing grade 316 stainless steel through additive manufacturing using laser and electron beam melting has been developed and tested. The research group at Sports Tech Research Centre found that the components needed for the reactor could be successfully manufactured using the Electron Beam Melting (EBM) method and that the material properties in as build components are excellent and meet the high demands.

The next step in the Fusion for Energy project is to gather an international consortium of companies that can manufacture 316L components for the ITER reactor. Here Sports Tech Research Centre plays an important role of transferring 316L manufacturing technology from the experimental machine at Mid Sweden University to an industrial environment spin-off company AIM Sweden, having tight links to the research group.

The project is funded by Fusion For Energy (F4E).