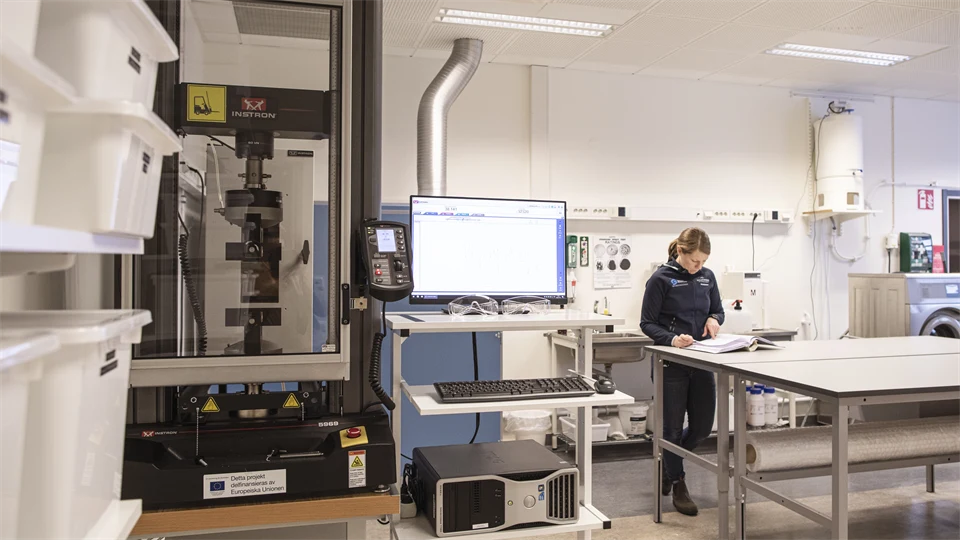

Materials testing

The lab for materials testing is a unique test environment and essential resource for both manufacturing companies, research and education. Here, everything from materials to finished products can be tested, mainly textiles.

Most tests and analyses can be performed, and everything from small pieces of material to entire garments or tents can be tested. One of our strengths is that we develop own methods and concepts, combining them to make the tests as realistic as possible. We also perform tests according to current ISO standards, but are not accredited.

In cooperation with us, companies can after shorter training gain access to the entire lab or individual machines to use as part of their material- and product development. Our researchers and research engineers can also assist in the process.

In the lab, there are several machines to test realistic load of different materials and products. We can among other things apply water pressure to the fabric to check its waterproofness, abrade it with sandpaper to simulate harsh wear, or tear the fabric apart in freezing temperatures and study the changes in material properties.

Examples of tests that can be performed:

- Water vapour permeability

- Waterprofness

- Water repellency (spraytest)

- Air permeability

- Martindale abrasion

- Pilling tendency

- Fast weathering (changes under UV, high humidity and elevated temperatures)

- RBF (Rotating Beam Fatigue, metal fatigue testing)

- Tear properties (also in freezing temperatures)

- Mechanical properties (stress-strain, loading capacity etc.)

- Microscopy (optical and scanning electron microscopy)