Bigasyn

In Sweden, about 1.2 TWh biogas vehicle fuel is produced each year. Biogas as a vehicle fuel has been commercialized well in Sweden.

However, further development of the biogas market is limited by the amount of available organic waste as well as the number of biogas filling station. On the other hand, biomass can be gasified into syngas and then synthesized into bio-SNG through catalytic methanation, or biomass gasification can be integrated into the biogas system to produce methane through biological methanation. In this way, biomethane vehicle fuel can give a significant contribution to the Swedish target: Free fossil fuel traffic by 2030. Biogas can be an important energy carrier in the future smart energy grids. By means of biogas system for electricity and vehicle fuel production, the increased proportion of variable renewable electricity (solar and wind) on the grid can be balanced. More importantly for Sweden, biogas production can be increased to a full scale to meet transport fuel demand by integrating biomass gasification into biogas system. For this purpose, a novel pathway is proposed to be studied in this project:

Biomass gasification > H2+CO > Biogas digester > Upgrading > Natural gas network

The project goal is 1) to further develop biomass dual-fluidized bed gasifier to produce a good quality syngas, and 2) to study the biogas production from biological methanation or bio-methanation of syngas. The technology feasibility, the bioreactor design, the process synergy and the integration of the gasification plant with the biogas plant will be studied in detail in cooperation with Chalmers.

A techno-economic analysis will be made for commercialization of vehicle fuel production from biomass gasification and digestion, together with Härnösand Energi & Miljö AB, MittSverige Vatten AB, Biogas i Mellannorrland AB, Sundfrakt AB and TRB Sverige AB.

Laboratory facility

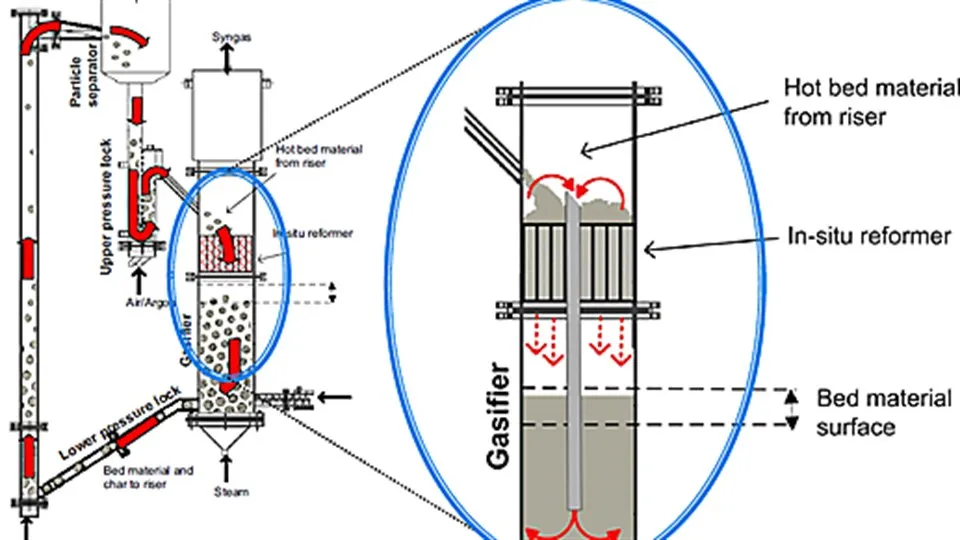

The laboratory facility of the bioenergy research group is centralized with a pilot plant of biomass dual fluidized bed gasifier (DFBG) as shown below, which was developed by the bioenergy group. The DFBG gasifier consists of a bubbling fluidized bed steam gasifier and a circulating fluidised bed riser combustor, and has the biomass treatment capacity of 150 kWth, i.e. approx. 25 kg biomass feed per hour. The gasifier and the combustor have a height of 2.5 and 3.1 m and inner diameters (i.d.) of 300 and 90 mm, respectively. A good gas-solid contact can be realized by an in situ reformer installed above the dense bed of the fluidized bed gasifier but under the hot bed material return position. Such an in situ reformer, similar to an upper fluidized bed of olivine, is developed by the bioenergy group as shown below. Biomass is first devolatilized in the bottom fluidized bed. The volatile from biomass pyrolysis then goes through the upper part in situ reformer and experiences cracking and reforming of tars and CH4 in the hotter reformer.

Facts

Project period

170901—210101

Subjects

Research groups

Project leader