av

Treesearch Progress 2022

On 11-12 May 2022 we participated in Treesearch Progress at Vildmarkshotellet in Kolmården.

In total, about 200 people from academia, industry and financiers gathered at the conference.

Hafizur Rahman, Siwen An, Rana Alimohammadzadeh and Per Engstrand presented the research at FSCN and Mid Sweden University in parallel sessions and participated in the conference.

Keynote speakers were Dimitris Athanassiadis from Swedish University for Agricultural Sciences and Orlando Rojas from BioProducts Institute, University of British Columbia.

Daniel Söderberg and Karin Larsdotter presented the pillars of tree research and many speakers from partner companies and core partners gave short presentations.

There were also four parallel sessions with speakers who shared their research results from the academy, a total of 40 researchers presented their results with lots of interesting questions and dialogues. Four of them were from Mid Sweden University:

1. Development of improved CTMP with even sulphonate distribution at fiber level using new ED-XRF analysis

Hafizur Rahman, Project Assistant at Mid Sweden University

Minimizing the fiber property distribution would have the potential to improve the pulp properties and the process efficiency of chemimechanical pulp (CTMP). To achieve this, it is essential to improve the level of knowledge of how evenly distributed the sulphonate concentration is between the individual CTMP fibers. Since wood chips can vary in quality depending on pulpwood chipping method and sawmill chipping as well as on chip screening system it is challenging to develop an impregnation technology that allows for an even distribution of the sodium sulphite (Na2SO3) impregnation liquid. It is therefore necessary to be able to measure the distribution of sulphonate groups within the wood chips and individual fibers, i.e., on a micro-scale level. Typically, the degree of unevenness, i.e. the amount of fiber sulphonation and softening prior to defibration, is unknown on a micro-level due to excessively robust or complex processing methods. In the event that it existed, we could better understand how sulphonation works before defibration in order to improve impregnation. The strategy for improving the impregnation technology is to study different impregnation systems in lab and pilot scale on wood chips produced in different ways in a pilot scale pulpwood chipper and a pilot scale sawmill chipper. This is to minimize the difference in sulphonate content between different fibers. To study the influence of impregnation improving processes we have developed a laboratory scale miniaturized energy dispersive X-ray fluorescence (ED-XRF) method that can measure sulphur (S) distribution at fiber level.

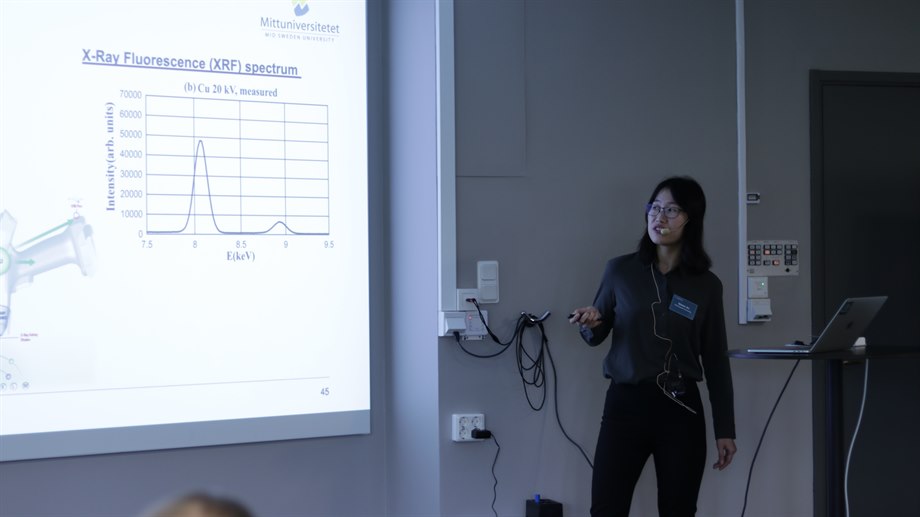

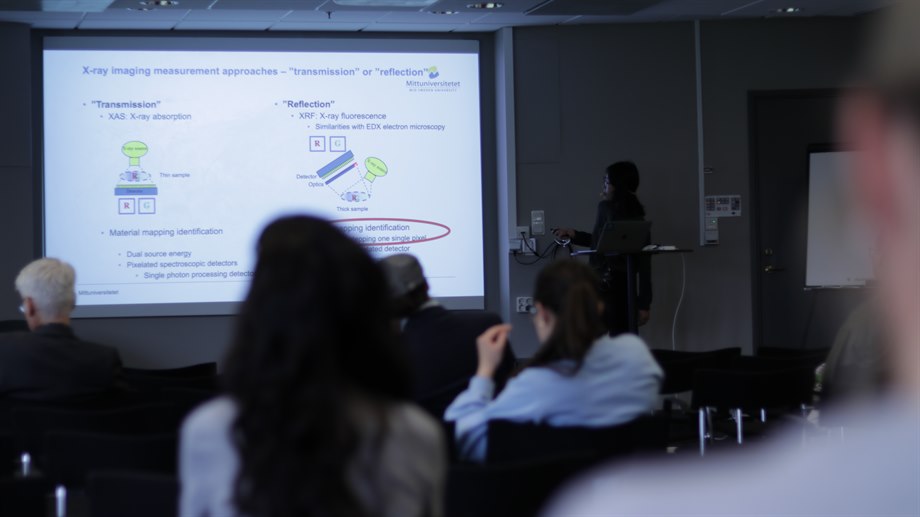

2. Synchrotron measurements of sulphonation homogenity on single fiber level form Chemical Thermo Mechanical Pulp (CTMP)

Siwen An, PhD student at Mid Sweden University

In order to improve process efficiency, one of the key parameters during CTMP impregnation is to prevent uneven distribution of sodium sulphite (Na2SO3). Hence measurements of sulphur distribution on single fibre level has been performed at the synchrotron facility APS, Advanced Photon Source, at the Argonne National Laboratory in the USA. Elemental mapping images of several different CTMP samples are retrieved by using a synchrotron beam with one micrometer scanning step. Depending on the chemical pre-treatment of wood chips and temperature, pressure profile and refiner conditions, the position in the fibre wall where the fibre-fibre separation takes place will differ. Some fibre surfaces are exposed to lignin while other will have minor lignin contact, which might cause uneven sulphur distribution within single fibres. On a larger scale, fibres from the outer parts of the wood chips have more impregnation than the fibres coming from the inner part of the same wood chip. Significant uneven distribution of sulphur between fibres are revealed in the images of CTMP samples. On individual fibre level, it is noticed that the sulphur impregnations is concentrated mainly in the fibre shell. Although the main focus is the Sulphur (S) distribution, other elements including Chlorine (Cl), Potassium (K), Calcium (Ca), Manganese (Mn), Iron (Fe), Copper (Cu) and Zinc (Zn) are analysed as well. One purpose to these synchrotron measurements is to verify a sulphur distribution measurements setup developed for use with an X-ray tube in lab or on site at a factory.

3. Nature-Inspired Design of Superhydrophobic Cellulose- and Nanocellulose-Based Materials: A Novel Water-based Composition

Rana Alimohammadzadeh, Researcher at Mid Sweden University

Superhydrophobic surfaces are highly influential in the industrial sector due to their water-repellent, self-cleaning, friction-reducing, and antifouling properties. Several examples of superhydrophobic surfaces exist in nature (e.g. butterfly wings, water strider’s feet, plant leaves). Fluorocarbons have been used extensively in the creation of superhydrophobic surfaces. However, they are toxic and accumulate in nature. Cellulose is an important natural biopolymer. However, pure cellulose-based materials are water sensitive and disintegrate in an aqueous environment. We have designed an eco-friendly and fluorine-free water-based composition for creating superhydrophobic cellulose- and nanocellulose-based materials (contact angle > 150°). The design and the catalytic chemistry of the bio-inspired surface functionalization will be presented and discussed.

Treesearch core partners

KTH, Chalmers, Linköping University, Luleå Tekniska Universitet, Lund University, Mid Sweden University, SLU, Stockholms universitet, Karlstads Universitet, Ahlström Munksjö, Billerud Korsnäs, Holmen, Neste, SCA, Södra, Stora Enso, Tetra Pak, RISE, Vinnova, Bio Innovation and Knut and Alice Wallenberg Foundation.