Micro X‑ray

Development of improved CTMP with even sulfonate distribution at fiber level using new XRF analysis.

Minimizing the fiber property distribution would have the potential to improve the pulp properties and the process efficiency of chemimechanical pulp (CTMP).

To achieve this, it is essential to improve the level of knowledge of how evenly distributed the sulfonate concentration is between the individual CTMP fibers. Since wood chips can vary in quality depending on pulpwood chipping method and sawmill chipping as well as on chip screening system it is challenging to develop an impregnation technology that allows for an even distribution of the sodium sulfite (Na2SO3) impregnation liquid.

It is therefore necessary to be able to measure the distribution of sulfonate groups within the wood chips and individual fibers, i.e., on a micro-scale level. Typically, the degree of unevenness, i.e., the amount of fiber sulfonation and softening prior to defibration, is unknown on a micro-level due to excessively robust or complex processing methods. In the event that it existed, we could better understand how sulfonation works before defibration in order to improve impregnation.

The strategy for improving the impregnation technology is to study different impregnation systems in lab and pilot scale on wood chips produced in different ways in a pilot scale pulpwood chipper and a pilot scale sawmill chipper. This is to minimize the difference in sulfonate content between different fibers.

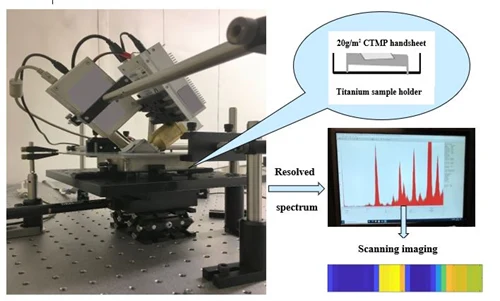

To study the influence of impregnation improving processes we aim to develop a laboratory scale miniaturized energy dispersive X-ray fluorescence (ED-XRF) method that can measure sulfur (S) distribution.

The purpose of this project is to improve the spatial resolution of an ED-XRF system using polycapillary-focusing optics, use industrial samples as reference, and introduce it into industrial laboratories for further development. The method can be applied to both offline and online impregnation equipment to improve process efficiency, process control, and product properties, as well as to find solutions to future impregnation problems.

Figure- Images of the ED-XRF lab setup for studying sulfonation degree

Facts

Project period

220801—231231

Partners

Research centers

Departments

Research groups

Project leader

Project members