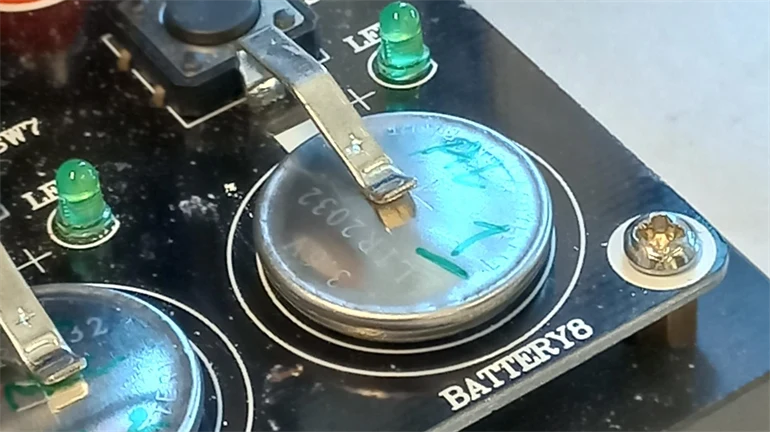

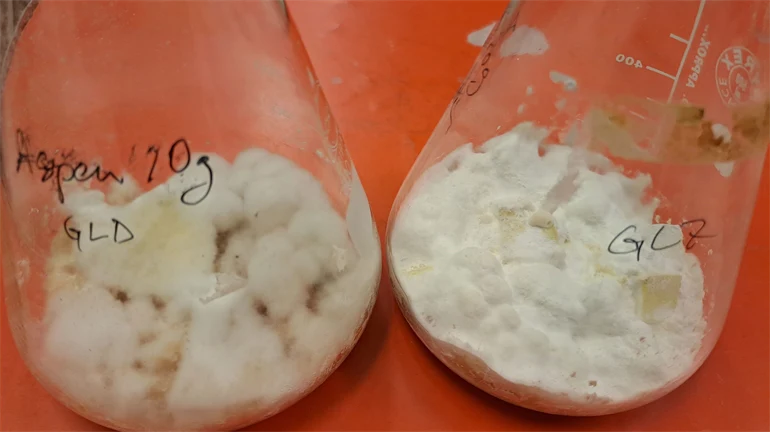

Aluminum Foil Coating with Graphene as Current Collector of LiFePO4 Cathode in Lithium-ion Battery (ALGCC)

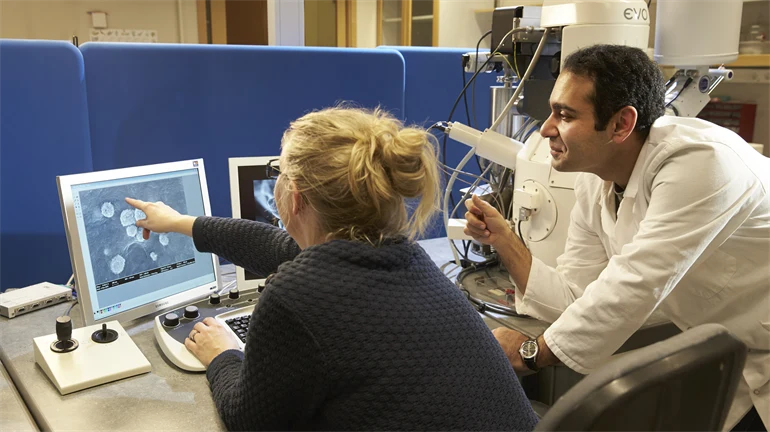

The aluminum current collector is a crucial component for various types of batteries. Al foil is used as current collector for LiFePO4 cathode in Lithium-ion batteries. While LFP is a suitable...