NeoPulp

NeoPulp is a Research Profile with a vision to build a pioneering research profile in fibre behaviour during pulping and papermaking processes.

Mid Sweden University has started a new 8-year research program called NeoPulp to learn how wood fibres behave in manufacturing processes converting them into products such as paper, board materials, 3D-formed packaging and other structural products.

Heterogeneity is a fundamental challenge in the industrial utilisation of all bio-based raw materials since it limits the efficiency at which the renewable raw material, energy and other resources can be used.

New perspective on the development of fiber properties

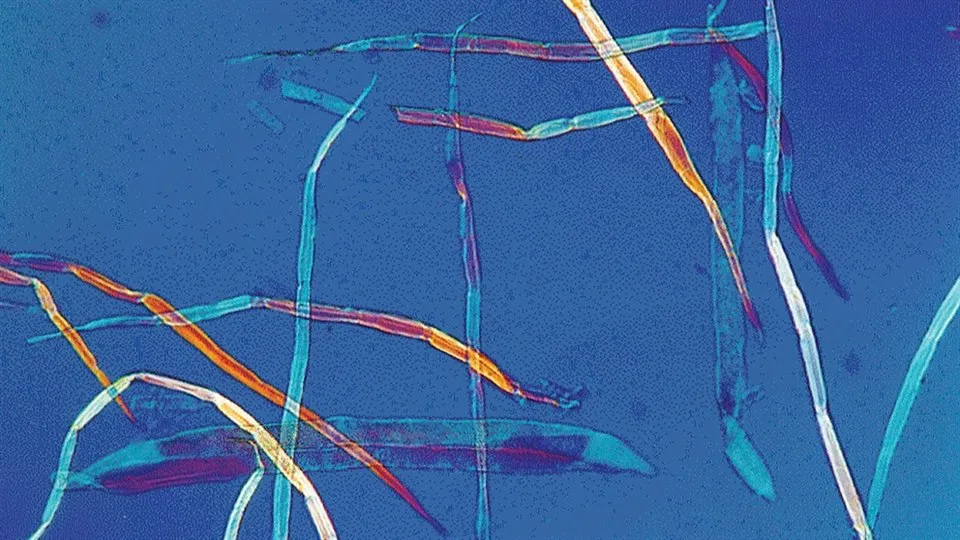

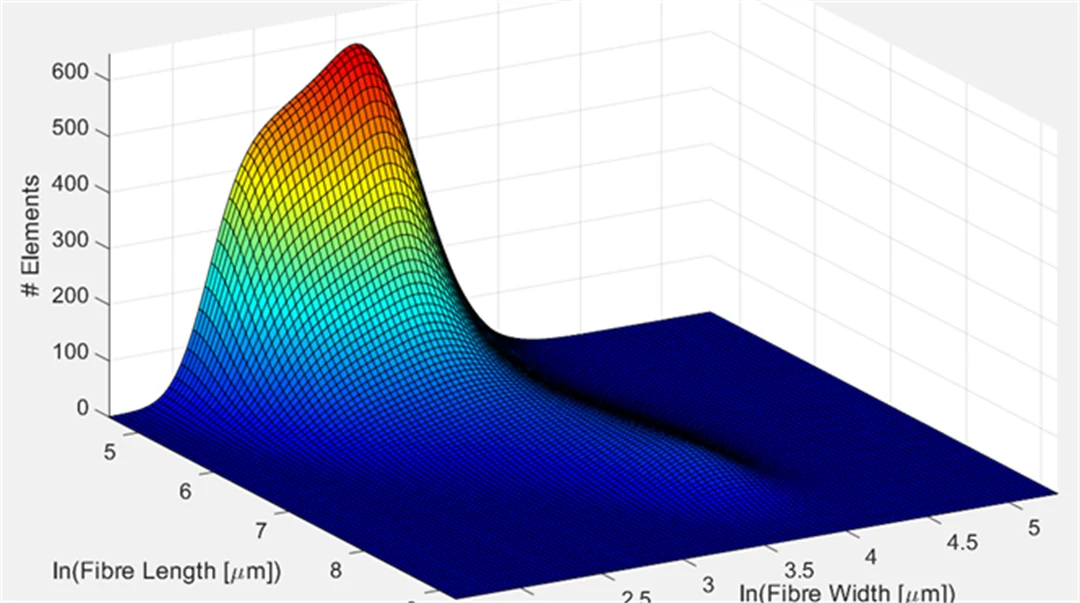

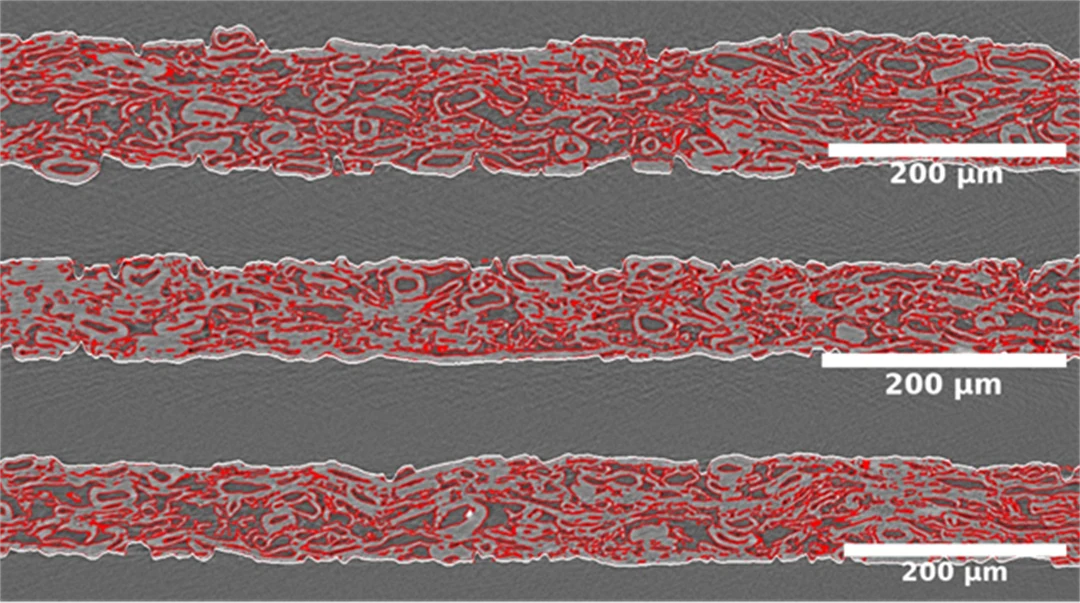

In NeoPulp, we focus on the heterogeneity between fibres. For some years now, it has been possible to measure geometric properties of large numbers (say 1.000.000) of fibres. This opens an opportunity for novel data-driven analysis of particle-level process phenomena and heterogeneity effects. We want to use the opportunity to proceed to a new level in the understanding of the processing behaviour of fibres for better resource efficiency and smaller footprint in the existing, upgraded and completely new manufacturing processes of fibre-based materials. We expect that the analysis of property distributions will prove fruitfil also for other bio-based and soft materials.

NeoPulp has three inter-connected research areas

- Analysis methods for measured distributions

- Mechanical interactions of fibres

- Consolidation of fibre-based materials

We are scientists in process engineering, computer engineering, statistical and fibre mechanics, physical chemistry and organic chemistry working together with researchers and engineers from industrial companies, institutes and other universities.

Get in touch if interested!

It is important to understand how fiber properties affect the performance of paper and board to improve our products and minimize environmental impact, Christer Sandberg, R&D specialist Holmen Paper.

Facts

Project period

210901—290930

Partners

Research centers

Project leader

Project members