Microfiber

A new XRF analysis develops high yield pulp with even sulfonate distribution at fiber level for improved renewable packaging.

This project has addressed the main bottlenecks of using environmentally friendly, renewable packaging materials since plastic dominates the packaging industry.

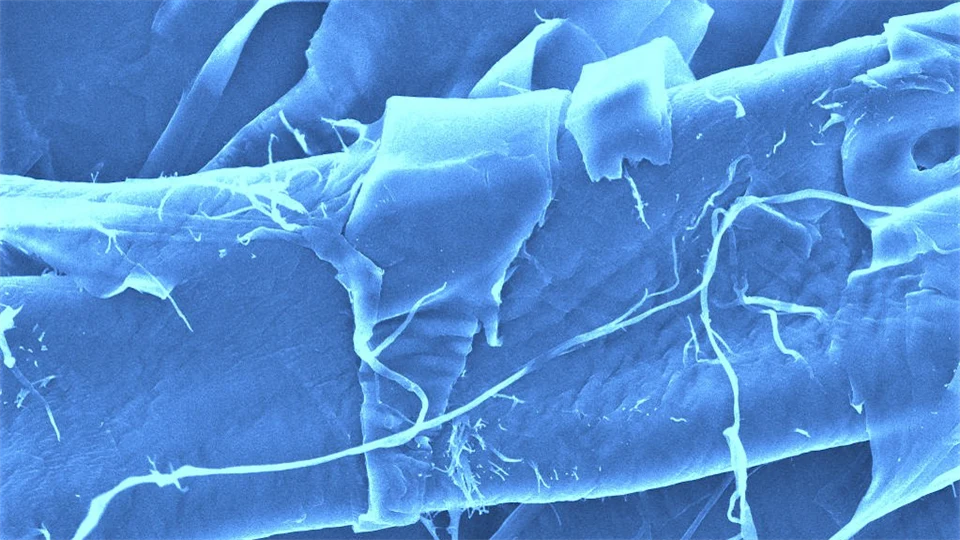

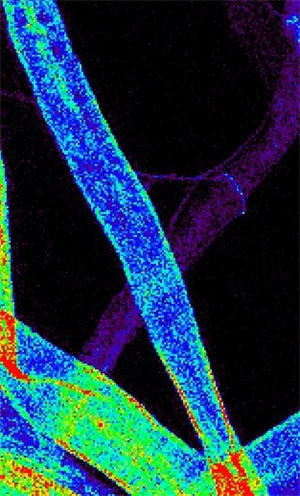

This interdisciplinary project aims to fundamentally resolve the degree of unevenness, i.e., the amount of fiber sulfonation and softening prior to defibration, which is unknown on a micro-level. Typically, the distribution of sulfonation in wood chips after impregnation is quite uneven, and therefore the degree of sulfonation of individual fibers is also uneven, see at Figure.

This phenomenon remains largely ununderstood. In chips, we intend to maximize sulfonate distribution by minimizing variation in fiber sulfonate content. A pulp made from softening chips can contain well-preserved fibers at yields greater than 95% and shives (rejected part) less than 1%, saving energy less than 200 kWh/h. Therefore, it is our main objective to study these dynamic processes, develop new methods and materials that will broaden the application of forest-based materials.

In order to reduce sulfite dosage to certain fiber separation and increase softening temperature, this project will revolve around ways to streamline or equalize the degree of sulfonation at the fiber level.

However, by impregnating wood chips with sodium and sulfur -based chemicals, we can be able to reduce sulfite doses between fibers, minimize the shives content (rejected part) and save energy at the chemical and chemical-mechanical pulping processes.

Figure. The visualization of single fiber sulfonation (APS 2-ID-D beamline, USA)

In this project, polycapillary optic lenses are using as the next step in the Micro-X-ray project. In the next phase for industrial lab, we aim to improve the evenness of sulfonation in fiber using a new polycapillary X-ray optic with additional Niacin chemical analysis method. In combination of two approaches, we want to improve efficiency of impregnation equipment, process control, and product properties, as well as find solutions to future impregnation issues of high yield pulps.

The project is financed by the J. Gust.Richert foundation.